- Products

- Cables

- Duct Cables

- Mini Nylon Loose Tube Cable

OSA-F(+)-(6-288)MLT

Mini Nylon Loose Tube Cable

Mini Nylon LT 6-288 fibers TIA598

- Up to 288 fibers

- Suitable for installation in duct

- Excellent optical performance with low loss fibers

- A dry cable design - easy to prepare and identify fibers

- Fully dielectric design

- Excellent mechanical performance

- UV stabilised materials

- Termite protected design

- Up to 288 fibers

- Suitable for installation in duct

- Excellent optical performance with low loss fibers

- A dry cable design - easy to prepare and identify fibers

- Fully dielectric design

- Excellent mechanical performance

- UV stabilised materials

- Termite protected design

The mini nylon loose-tube cable series combines ultra-low attenuation, state of the art installation performance and ultra compact size. Reduced diameter loose tube combines the same excellent performance of standard nylon loose tube, in a robust and compact form factor. Its reduced size is a benefit to both asset owners and installers, facilitating faster installation, easier handling, and less duct congestion.

The cables are based on a dry waterblocked concentric core, slim loose tube design with up to 12 tubes per cable.

The cables have one or two layers of protective SZ laid tubes made of a robust PBT compound where each tube has 12 fibers. (excluding 6f)

The tubes are jacketed by a black HDPE and blue Nylon sheath in compliance with AS 1049.

The design facilitates easy fiber preparation and mid-span access.

-MLTN.FRNT.png?1715850041897&width=775&height=442&name=OSA-FSM-(6-144)-MLTN.FRNT.png)

- Primary coated fiber: Silica, acrylate

- Filler: Thixotropic gel

- Loose tube: Polybutylene terephthalate

- Central strength member: Glass fiber reinforced plastic

- Wrapping: Water blocking yarns

- Inner sheath: High density polyethylene

- Outer jacket: PA 12

Black fillers can replace tubes.

Ripcords are included underneath the inner sheath.

CSM is up-coated in black PE where necessary

Double layer design for fiber counts greater than 144

Technical Information

| Product Color | Blue sheath |

|---|---|

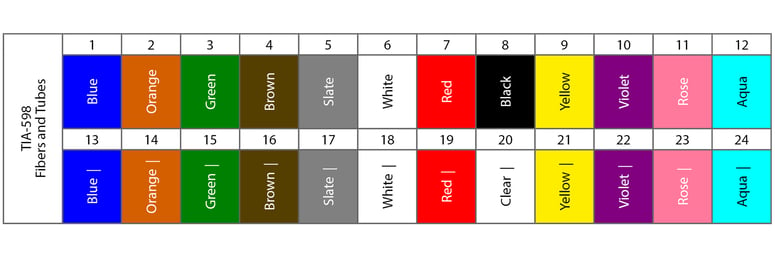

| Color Code | TIA598 |

| Temperature, Operation [°C] | -20 to +70 |

| Temperature, Storage [°C] | -20 to +70 |

| Temperature, Installation [°C] | 0 to +50 |

| Fiber Type | G657A1;G652D;OM3;OM4 |

| Attenuation @Wavelength [nm] | 1310/1550/1625 [850/1300] |

| Maximum Attenuation [dB/km] | 0.36/0.23/0.27 [3.5/1.5] |

| Conformance |

Temperature Range: IEC 60794-1-22-F1

|

| Marking | The sheath is indelibly printed every metre in a contrasting colour using the inkjet Method. The marking includes the manufacturer, part number, manufacturing date, batch number and metre marking. |

| Ordering Information | Supplied lengths: 2 km, 4 km ±5% Other fiber types available by special order. |